Boral Cement is a trusted leader in Australian construction materials. Our operations include advanced manufacturing facilities, strategically located sites, and joint ventures that strengthen our supply chain. With nationwide distribution and technical expertise, we deliver consistent quality for projects of all sizes – from major infrastructure to home improvements.

Explore Our Cement Range

Choose the right product for your project. Boral offers cement solutions for every application, backed by decades of experience and innovation.

Why Choose Boral Cement?

- Australian Made and trusted for 80 years

- Advanced manufacturing assets and strategically located sites

- Strong joint ventures and partnerships for supply security

- Nationwide distribution network for timely delivery

- Commitment to sustainability and low-carbon solutions

Our Operations & Network

Boral Cement is an integrated cement manufacturer, with limestone reserves in NSW supporting our Berrima plant and a grinding footprint at Berrima, Maldon, Geelong and Brisbane. This network gives us operational flexibility to meet demand across the east coast.

We service customers efficiently through eight key metropolitan and regional depots across NSW, Victoria and Tasmania, with rail, road and sea links that move cementitious materials from Berrima and Geelong to where they are needed. In Queensland, our Sunstate Cement joint venture supplies external and downstream demand.

Our fly ash capability includes processing at Tarong Power Station and supply through Flyash Australia, supporting circularity and carbon reduction.

Learn more about our operations.

Sustainable Cement Manufacturing

We’re reducing carbon emissions through innovative processes and alternative materials.

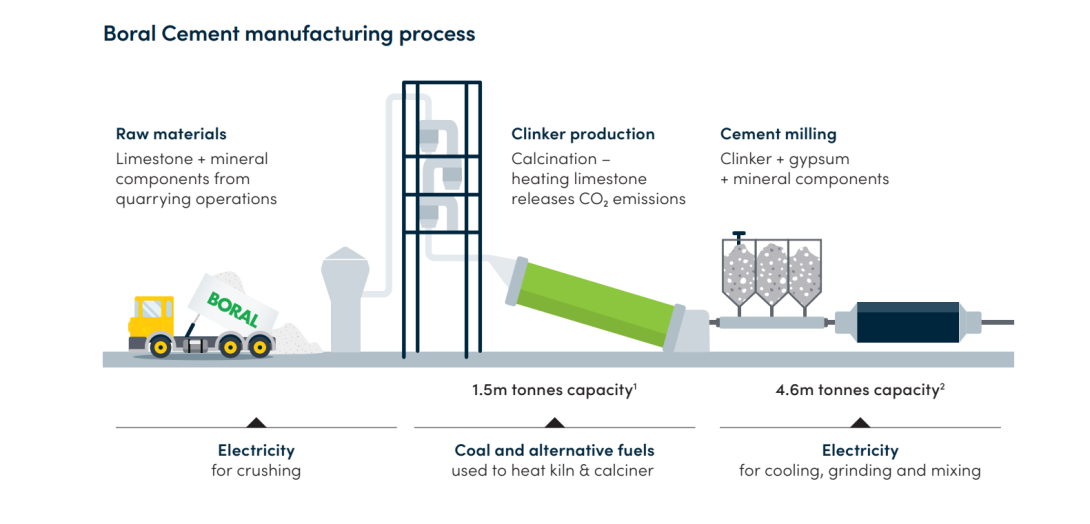

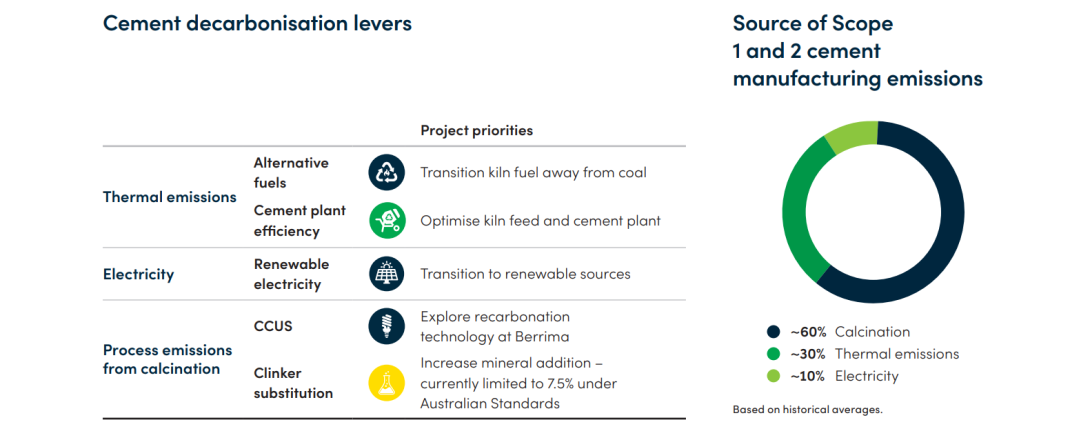

Cement production has a significant carbon footprint. Boral is decarbonising cement by improving manufacturing efficiency, expanding the use of supplementary cementitious materials and reducing the carbon intensity of clinker and cement we import and purchase.

These actions help lower embodied carbon in concrete while supporting performance requirements for major projects.

Frequently Asked Questions

What type of cement should I use for concrete slabs and driveways?

For most residential slabs and driveways, General Purpose GP Cement is suitable and cost effective. It is manufactured from Portland cement clinker and gypsum and is widely used in concrete slabs, driveways, mortars and grouts. Always follow local standards and mix design guidance for site conditions.

Does Boral supply lower carbon options for concrete?

Yes. You can replace a portion of Portland cement with supplementary cementitious materials such as fly ash and Enviroment® ground granulated blast furnace slag. These materials can improve durability, reduce heat of hydration and enhance resistance to chlorides and sulphates, which is valuable for mass pours and aggressive environments.

Where can I buy packaged cement near me?

Boral has a market leading position in packaged cement and dry mix in NSW, supplying through a trusted reseller network. Use the reseller finder on our site or contact us for assistance with local stockists.

How does Boral ensure reliable supply for large projects?

We combine Australian manufacturing at Berrima with grinding capability at Berrima, Maldon, Geelong and Brisbane, and we operate an extensive depot network across NSW, Victoria and Tasmania. We also partner through Sunstate Cement in Queensland. This integrated network helps us meet demand and deliver consistently.

Ready to specify or order cement for your next project?

Contact us to receive a quote.