What is a Quarry? Understanding Quarrying and Its Importance

Definition of a Quarry

A quarry is an open-pit site where natural materials such as rock, sand, gravel and stone are extracted from the earth. These materials, known as aggregates, are essential for building infrastructure like roads, bridges, homes and schools. Quarries are carefully planned and operated under strict environmental and safety regulations to ensure minimal impact on surrounding communities and ecosystems.

What Does Quarrying Mean?

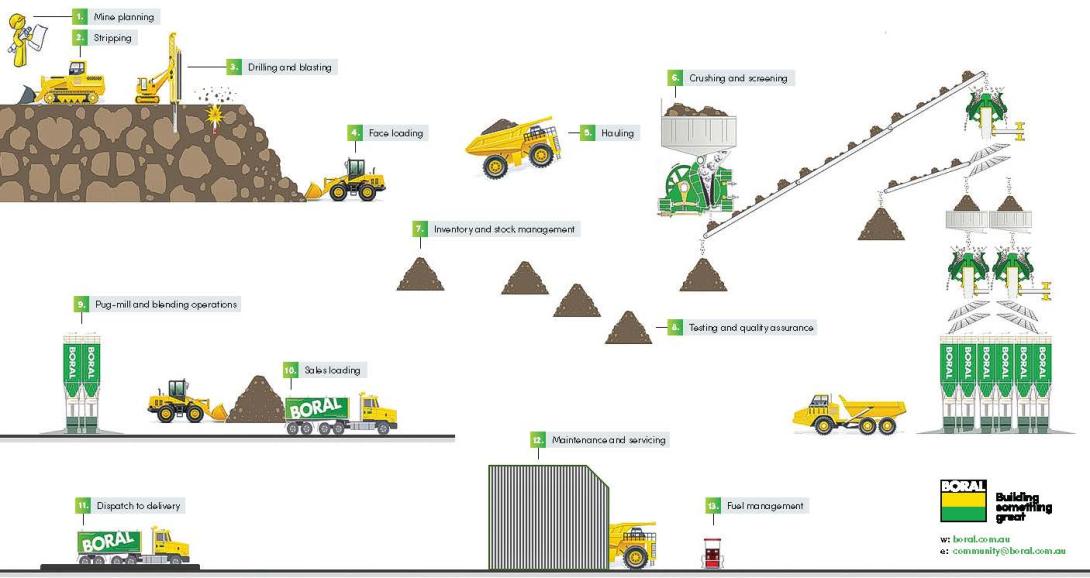

The meaning of quarrying extends beyond excavation. It refers to the entire process of identifying, extracting and processing raw materials from the earth. At Boral, quarrying begins with site preparation, followed by drilling and controlled blasting to break up the rock. The material is then crushed, screened and sorted into various sizes for use in concrete, asphalt, road base and other construction applications. This process ensures a consistent supply of high-quality materials that meet the needs of Australia’s growing infrastructure.

Why Are Quarries Important?

Quarries are vital to Australia’s economic development and everyday life. Each year, the construction industry requires more than 200 million tonnes of quarry materials. These materials are used in everything from residential housing and commercial buildings to major infrastructure projects like highways, airports and rail networks.

In South Australia alone, the resources sector, which includes quarrying, contributed over $9.5 billion in direct and indirect spending to the state’s economy in the 2023–24 financial year. Quarrying not only supports thousands of jobs but also plays a key role in keeping construction costs down by supplying materials close to where they are needed. This proximity reduces transportation distances, lowers emissions and helps minimise traffic congestion.

Boral Quarries: Supporting Australia’s Growth

As one of Australia’s leading construction materials companies, Boral operates more than 75 quarries across the country. These sites produce around 30 million tonnes of materials annually, including aggregates, crushed rock, road base, sand and specialty products such as gabion rock and rail ballast.

Our quarries are strategically located near major cities and infrastructure corridors to ensure efficient delivery and reduced environmental impact. For example, Linwood Quarry in Adelaide is one of South Australia’s largest hard rock quarries, supplying high-quality aggregates to projects like the Southern Expressway and Adelaide Airport. Similarly, Peppertree Quarry in New South Wales and Ormeau Quarry in Queensland are key suppliers to their respective regions.

Quarry Near Me: Find Your Local Boral Quarry

If you're searching for a quarry near me, Boral makes it easy to find one. Our Location Finder allows you to explore nearby sites and discover the range of materials available. Whether you're a contractor, builder or local council, our team can help you find the right quarry products for your project.

How Boral Quarries Operate

Our quarrying process is designed for efficiency, safety and environmental care:

- Site preparation – vegetation and topsoil are removed and stored for rehabilitation

- Drilling and blasting – rock is broken into manageable sizes

- Crushing and screening – materials are processed into different sizes and grades

- Stockpiling and transport – products are loaded onto trucks for delivery

We also invest in dust suppression, water recycling, and rehabilitation to minimise our environmental footprint.

Need help choosing the right quarry product?

Contact our team to speak with an expert.

Have feedback about your local quarry?

Email your concerns to community@boral.com.au.